Developments in materials and their impact on furniture design

- Theo Silkstone

- Apr 7, 2025

- 13 min read

Updated: Feb 3

Selection of materials and processes is an integral part of the design process; materials are selected both for practical reasons and for textural contrast. Nowadays, when starting a new design - whether it's crafting a record player stand, a bespoke walnut office desk, or sculptural wall art - furniture makers have a plethora of materials and processes from which to choose. Selecting the most appropriate material now is based on a range of criteria including aesthetic preferences, structural performance, facilities available, cost, durability and environmental attitudes. However, this has not always been the case. In the past, the range of materials available was severely restricted and for centuries furniture design was limited by what could be made with locally available materials. As more materials and processes have been discovered, new possibilities for furniture design have emerged. It is my belief that nothing has so influenced the changes in furniture design as the emergence of new materials and processes. This essay will run through some of the key developments in materials and their impact on Western furniture design.

When people think of furniture, most think of wood. This is for good reason as for centuries it has been the primary material used in furniture design. It is enduring, beautiful and, of course, available. In the UK, up until around 1600 most furniture would have been made only from locally available timbers such as oak, walnut, sycamore and cherrywood (Linley, Cator and Chislett, 2009)[i]. The resulting furniture was often heavy, with details added in the form of carvings, as in the Jacobean era. However, with the dawn of the Age of Exploration, new materials began to reach the UK and be introduced to furniture. Following the Renaissance, veneering gained popularity as a technique as it allowed furniture makers to achieve decorative effects using expensive exotic woods sparingly. These included rosewood from India and the East, ebony from Africa, and tortoiseshell from the South Pacific. Veneering greatly expanded design possibilities and led to the creation of ever more ornate and elaborate furniture pieces that, together with gold leaf gilding, defined much of the next couple of centuries. The work of Thomas Chippendale epitomizes this era of furniture making.

In the early 19th century, steam power provided mechanization of many processes, allowing for the mass production of much furniture. This included the efficient production of veneers. As a result, veneers became mainstream in Victorian furniture production. However, the automation of furniture production did not necessarily produce higher quality furniture. One notable exception is Michael Thonet, whose experiments in the production of bentwood furniture resulted in wonderfully designed chairs, most famously café chairs, being produced in huge quantities of some 400,000 annually, hitherto unknown in the world of furniture production (Encyclopedia Britannica, n.d.)[ii]. These designs are still being produced today.

The Industrial Revolution was also significant as it led to a prevalence of mass-produced iron and steel which facilitated the creation of new frameworks for furniture. In the US in 1906 the Larkin Office Chair, shown below in Figure 1 (collectiononline.design-museum.de, n.d.)[iii], was one of the first indoor metal seats and one of the first ‘modern’ chairs that made a significant break from the wooden furniture of the past (Lawson, 2013)[iv]. Experimentation with metal frames continued, and in 1919 the Bauhaus School was founded, which concentrated on free experimentation with colour, form and materials. It was from here that the tubular steel club chair, the B3, emerged as shown in Figure 2 (Museum of Modern Art, 2019)[v]. This was the first successful attempt since Thonet to align mass production with a new material and manufacturing technology. Tubular steel then reached its full potential with the development of the cantilever chair by Mart Stam, Figure 3 (Stuhlmuseum Burg Beverungen, 1998)[vi]. This is one of the most significant steps in furniture design history as it redefined the possibilities in terms of what a chair, the epitome of a functional object, could be.

Spurred on by these discoveries, experimentation with metals continued and in 1931 Jean Prouvé made use of the newest metal forming and welding processes of the time to create the Cite Armchair, as shown in Figure 4 (Lawson, 2013)[vii], which was radically different to anything that had come before. A further significant development in the use of metal included a chair made entirely from aluminium pressings by Rietlveld and the chair with cast-aluminium legs and a plywood shell that was produced by Clive Latimer and emerged from the utility scheme in the UK. This fed into many subsequent and very successful designs including the Aluminium Group in 1957 by Charles and Ray Eames which consisted of only six die-cast aluminium components. See Figure 5 (collectiononline.design-museum.de, n.d.) [viii].

The work of Breuer fed into the American style of Art Deco, which made extensive use of tubular steel, as well as other materials such as chrome, glass, laminates, veneers, ivory and tortoiseshell. Meanwhile, upholstered chairs tended to become overstuffed as fabrics became cheaper: for example, the Pelican chair by Finn Juhl in 1940, as shown in Figure 6 (finnjuhl.com, n.d.) [ix]. It should be noted that, whilst new materials led to the emergence of new forms and styles of furniture, developments were still taking place, influenced by these novel forms but using traditional materials. This included the work of Hans Wegner and his Peacock and Wishbone chair, the designs of which had modern forms influenced by the other design work going on at the time.

Plywood, a composite material made from thin layers of wood glued together with grains alternating at right angles, was commonly used in the 19th century, but gained significant popularity in the 20th century (Victoria and Albert Museum, n.d.)[x]. It is particularly advantageous as a material due to its stability, affordability and high strength. One of the greatest developments with plywood was achieved by Finnish architect Alvar Aalto, who in 1930 produced the first lamination of a large, complex one-piece form, the Paimio Armchair, as shown in Figure 7 (Victoria and Albert Museum, n.d.)[xi]. This had one of the largest impacts on subsequent manufacturing and design and it put wooden furniture, albeit laminated, back on the map as a worthy material for furniture design following a previous shift away from wood and towards metal and modernist and brutalist designs. Superb examples of the use of plywood around this time include: the DCM chair, designed by Charles and Ray Eames (Victoria and Albert Museum, n.d.)[xii] ; the Antelope chair designed by Ernest Race for the Festival of Britain in 1951 (collection.maas.museum, n.d.)[xiii]; and the Isokon Penguin Donkey of 1939 (Victoria and Albert Museum, n.d.)[xiv], as all shown in Figure 7.

Despite the innovative uses of metals and plywood, it was the development of plastics in the mid-20th century that had the most significant impact on furniture design. In the 1950s Eames expanded on their earlier work with plywood and started to produce novel forms, such as the DSR chair 1949-50 (Lawson, 2013)[xv] and La Chaise of 1958 (Eames Office, n.d.)[xvi], using fibreglass (see Figure 8). The new aesthetics possible using fiberglass led to a dramatic shift in design, although the process was too slow and expensive to allow their mainstream success. However it did pave the way for the organic forms possible using new plastics and large-scale injection molding in the following decade. Plastics provided designers with new possibilities due to their versatility, moldability, and wide range of colours. Iconic furniture pieces like the moulded plastic DSR chairs subsequently produced by Eames perfectly exemplify the creative application of plastics in furniture design and its versatility as a material.

In 1962 Robin Day and Hille produced a one-piece, injection-moulded polypropylene chair, with four moulding fixing bosses to allow it to be screwed to a variety of leg frames. More than 14 million of these chairs have since been sold. A further significant example of a new form evolving from the emerging technology was the cantilevered, monobloc injection-moulded plastic chair of Verner Panton in 1967, as shown in Figure 9 (www.artsy.net, n.d.)[xvii]. Shortly after this in 1969, Gaetano Pesce was the first designer to harness the properties of polyurethane foam in the production of the UP series of chairs, as shown in Figure 9 (The Museum of Modern Art, n.d.)[xviii]. The novel properties of the foam meant that the chairs could be packaged in a small, sealed bag before being opened and expanding once in-situ. This innovation is comparable to Thonet’s remarkable feat of packing 30 chairs in 1m3. Following a sharp (40%) rise in the price of plastics that came about as a result of the 1973 global energy crisis, the injection moulding of the ‘60s partially gave way with the invention of reaction injection moulding, which allowed for cheaper production, greater versatility in terms of material selection as well as more complex and precise forms. An example of this work is the Model 4794 Lounge chair by Gae Aulenti for Kartell, as shown in Figure 11 (pamono.co.uk, n.d.)[xix].

These developments in plastics meant that laminated wood, which had for the past three decades been mainstream in furniture design, as discussed above, lost some of its popularity. Furthermore, there were also other significant technological advances taking place in the realm of other engineered materials in the 1970s. These included: the production of materials such as medium-density fiberboard (MDF), which provided a cost-effective and more stable alternative to solid wood, and, later, board-surfacing processes such as foil wrapping and membrane pressing. Together these had a dramatic impact on the flat-pack market with companies such as IKEA incorporating MDF into its furniture from the late 1970s for reasons of cost and stability, whilst foil-laminated surfaces allowed a much wider range of colors, patterns and finishes to be applied whilst giving a smooth and durable finish. This became a hallmark of IKEA’s design aesthetic and, whilst no IKEA design may be regarded in and of itself as a design icon, the range of designs produced and their huge popularity have nonetheless had a huge impact on the furniture, and particularly fitted-furniture of homes today.

As workplaces became increasingly office-based in the latter half of the 20th century, a new market and impetus for furniture designed appeared: that of office furniture. These needed to be supportive and adjustable to allow different people to sit comfortably for a long period of time. Once again, the most dramatic developments in this field have been materials-led, with the Aeron and Mirra chairs leading the way. These are shown below in Figure 12. The Aeron Chair was launched in 1994 as the new generation of office chair (The Museum of Modern Art, n.d.)[xx]. Significantly on the materials front, the designers did away with foam and upholstery and instead developed a new material, Pellicle, that presented a uniform weave but with eight varied zones of tension to help engage the sitter[xxi] (Journal, 2016). It also came with a myriad of physical adjustments available. The Mirra Chair was then launched in 2003 and has in many ways replaced the Aeron chair as the leading office chair. Whilst the Aeron chair had extensive adjustability, the Mirra Chair achieved these superb ergonomics through passive adaptability provided by its Ultramid nylon TriFlex backrest (Lawson, 2013)[xxii]. This material can be produced at a lower cost and provides good postural support whilst also allowing air movement.

Towards the end of the 20th century there was an explosion of new materials and processes available. Alberto Meda’s Light Light Chair from 1987 redefined what was structurally possible through its use of carbon fibre and a Nomex composite honeycomb. The whole chair, shown below in Figure 13, weighed less than 1kg (The Museum of Modern Art, n.d.)[xxiii]. Another superb example of a chair that puts the materials at the heart of the design is Ron Arad’s Fantastic Plastic Elastic Chair (1997), shown in Figure 14 (Museum of Design in Plastics, n.d.)[xxiv]. Here the seat itself wraps around and creates the structure between the legs, replacing conventional cross struts. At about this time, there was also significant development in the use of thermoplastics, particularly polycarbonate and polypropylene which allowed, for the first time, the production of a completely clear plastic injection-moulded monobloc chair (La Marie Chair by Philippe Starck) and subsequently the Louis Ghost Chair and Kartell Papyrus Chair (Cimmermann, n.d.)[xxv]. Further advances in plastics include the use of a new thermoplastic Ultradur by Konstantin Grcic to produce a sleek but strong cantilevered monobloc Myto Chair (The Museum of Modern Art, n.d.)[xxvi].

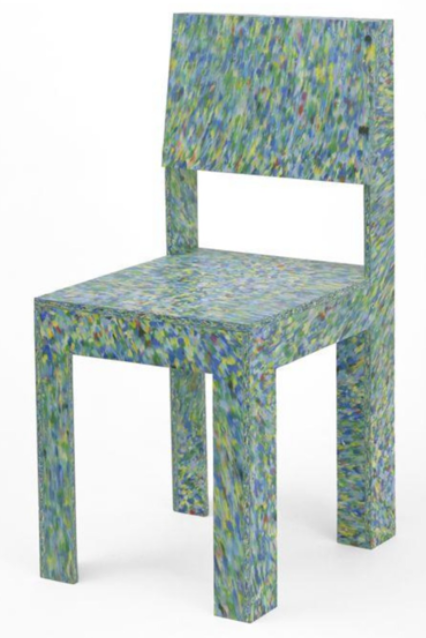

For the past few decades, one of the key impetuses for the change in materials has been the need for sustainability in design. As Stuart Lawson writes, “Design reflects the issues of the times and, at present, concerns about sustainability, ethical manufacture and responsible disposal are key”[xxvii] (Lawson, 2013). A lot of the innovation that is therefore happening today in furniture design is around the materials and processes used, and finding new and environmentally-friendly materials to design with. Furniture has been made directly from recycled objects, as well as produced using recycled plastics. For example, the RCP2 chair by Jane Atfield, as shown in Figure 15 ((Museum, n.d.)[xxviii]), is made entirely of recycled plastic bottles and was pioneering in 1996 when it was manufactured. Whilst iconic on the design front, one of the first examples to leave the galleries and exhibitions and hit the mainstream market was Herman Miller’s Aeron Chair in 1994. With 94% of its structure made from recycled materials, it heralded a new era in corporate responsibility that is now almost a point of necessity for most brands.

As well as recycled materials, there has also been a significant shift towards using natural materials. In 2011 Werner Aisslinger was the first person to produce a monobloc chair made from entirely natural fibres in his Hemp Chair, as shown in Figure 16 (Yatzer, 2011)[xxix]. This material had originally been developed for the automotive industry to provide an environmentally friendly alternative to plastic door panels. Further examples of recent experimentation with materials include the Imprint chair (Figure 17 (Lawson, 2013) [xxx]) by Johannes Foersom and Peter Hiort-Lorenzen in 2005 that is manufactured with Cellupress, which is cellulose, produced in sheets and then heated under pressure; and Doshi Levien’s bio-composite Impossible Wood chair (Figure 18 (Lawson, 2013) [xxxi]), which is injection moulded using a thermoplastic composite of 80% wood fibre and 20% polypropylene. This is a brilliant example of the material-led developments in manufacturing processes being re-applied to new materials that reflect the mood of the times.

As materials have evolved, so too has furniture design, with designs reflecting the materials of the time. In today’s world, environmental concerns are foremost and so it is to be expected that the designs of the future will comprise materials that reflect this. One interesting development that has arisen from this is in fact the circling back around to the benefits of making furniture with locally sourced wood. This is an approach that has been showcased by the work of Sebastian Cox whose designs are made with a “nature-first perspective”, using smaller branches, hewn wood and unusual species of trees to make efficient use of locally sourced wood. Recycling is certainly a step in the right direction but manufacture that encourages the planting of trees and carbon capture is even better.

[i] Linley, D., Cator, C. and Chislett, H. (2009). Star pieces : the enduring beauty of spectacular furniture : with 320 illustrations. London: Thames & Hudson.

[ii] Encyclopedia Britannica. (n.d.). Michael Thonet | Austrian furniture maker. [online] Available at: https://www.britannica.com/biography/Michael-Thonet.

[iii] collectiononline.design-museum.de. (n.d.). Vitra Design Museum: Collection. [online] Available at: http://collectiononline.design-museum.de/#/en/object/44695?_k=87tfrl [Accessed 30 May 2023].

[iv] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[v] The Museum of Modern Art. (2019). Club chair (model B3). [online] Available at: https://www.moma.org/collection/works/2851.

[vi] Stuhlmuseum Burg Beverungen (1998). Der Kragstuhl. Walther Konig Verlag.

[vii] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[viii] collectiononline.design-museum.de. (n.d.). Vitra Design Museum: Collection. [online] Available at: http://collectiononline.design-museum.de/#/en/object/35355?_k=u0yj5g [Accessed 31 May 2023].

[ix] finnjuhl.com. (n.d.). Pelican Chair by Finn Juhl | House of Finn Juhl. [online] Available at: https://finnjuhl.com/collection/lounge-chairs/pelican-chair.

[x] Victoria and Albert Museum. (n.d.). V&A · A short history of plywood in ten-ish objects. [online] Available at: https://www.vam.ac.uk/articles/a-history-of-plywood-in-ten-objects#:~:text=The%20technique%20has%20been%20around.

[xi] Victoria and Albert Museum. (n.d.). V&A · A short history of plywood in ten-ish objects. [online] Available at: https://www.vam.ac.uk/articles/a-history-of-plywood-in-ten-objects#:~:text=The%20technique%20has%20been%20around.

[xii] Victoria and Albert Museum. (n.d.). V&A · A short history of plywood in ten-ish objects. [online] Available at: https://www.vam.ac.uk/articles/a-history-of-plywood-in-ten-objects#:~:text=The%20technique%20has%20been%20around.

[xiii] collection.maas.museum. (n.d.). ‘Antelope’ chair by Ernest Race. [online] Available at: https://collection.maas.museum/object/36793 [Accessed 31 May 2023].

[xiv] Victoria and Albert Museum. (n.d.). V&A · The sophisticated Modern home. [online] Available at: https://www.vam.ac.uk/articles/the-sophisticated-modern-home.

[xv] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[xvi] Eames Office. (n.d.). LA CHAISE. [online] Available at: https://www.eamesoffice.com/the-work/la-chaise-2-2/.

[xvii] www.artsy.net. (n.d.). Verner Panton, Herman Miller | Panton Chair (Blue) (1967) | Artsy. [online] Available at: https://www.artsy.net/artwork/verner-panton-panton-chair-blue.

[xviii] The Museum of Modern Art. (n.d.). Gaetano Pesce. Up 5 Lounge Chair with Up 6 Ottoman. 1969 | MoMA. [online] Available at: https://www.moma.org/collection/works/2223.

[xix] pamono.co.uk. (n.d.). Space Age Italian Black Polyurethane Model 4794 Lounge Chairs by Gae Aulenti for Kartell, 1970s, Set of 2. [online] Available at: https://www.pamono.co.uk/space-age-italian-black-polyurethane-model-4794-lounge-chairs-by-gae-aulenti-for-kartell-1970s-set-of-2 [Accessed 31 May 2023].

[xx] The Museum of Modern Art. (n.d.). Donald T. Chadwick, William Stumpf. Aeron Office Chair. 1992 | MoMA. [online] Available at: https://www.moma.org/collection/works/3734.

[xxi] Journal. (2016). Herman Miller ‘Remasters’ Its Iconic Aeron Chair - Architizer Journal. [online] Available at: https://architizer.com/blog/practice/materials/herman-miller-re-masters-aeron/ [Accessed 30 May 2023].

[xxii] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[xxiii] The Museum of Modern Art. (n.d.). Alberto Meda. Light Light Chair. c. 1987 | MoMA. [online] Available at: https://www.moma.org/collection/works/3745 [Accessed 31 May 2023].

[xxiv] Museum of Design in Plastics. (n.d.). Fantastic Plastic Elastic chair. [online] Available at: https://www.modip.ac.uk/artefact/aibdc-002079 [Accessed 31 May 2023].

[xxv] Cimmermann (n.d.). Kartell Papyrus Chair. [online] Cimmermann. Available at: https://cimmermann.uk/products/kartell-papyrus-chair [Accessed 31 May 2023].

[xxvi] The Museum of Modern Art. (n.d.). Konstantin Grcic. MYTO chair. 2007 | MoMA. [online] Available at: https://www.moma.org/collection/works/113881 [Accessed 31 May 2023].

[xxvii] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[xxviii] Museum, V. and A. (n.d.). RCP2 chair | Atfield, Jane | V&A Explore The Collections. [online] Victoria and Albert Museum: Explore the Collections. Available at: https://collections.vam.ac.uk/item/O114267/rcp2-chair-chair-atfield-jane/.

[xxix] Yatzer. (2011). The Hemp Chair by Werner Aisslinger. [online] Available at: https://www.yatzer.com/The-Hemp-Chair-by-Werner-Aisslinger.

[xxx] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

[xxxi] Lawson, S. (2013). Furniture design : an introduction to development, materials and manufacturing. London England: Laurence King Publishing.

Comments